Scope of Work

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

The use of 6" fiberglass conduits for MV duct banks presented significant challenges due to their rigidity and limited flexibility. This required precise long-distance alignment to prevent misalignments, joint stress, or installation difficulties.

SOLUTIONS WE PROVIDED

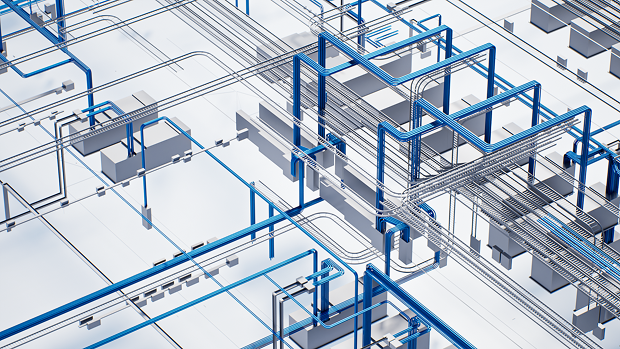

- Developed accurate long-distance routing to keep conduit runs as straight as possible, minimizing stress and reducing misalignment risks.

Project Goals

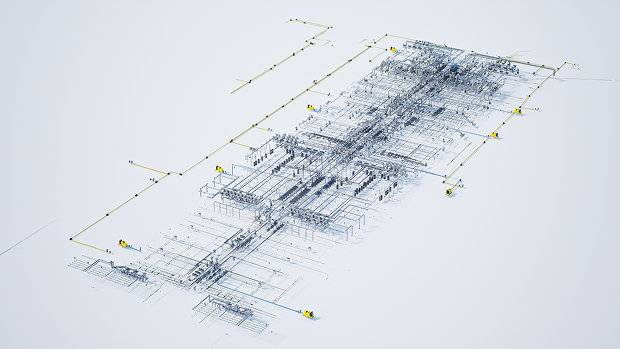

Archiving as detailed BIM model of electrical systems as possible to ensure proper planning and coordination to minimize rework.

Proven Advantages

Innovative Solutions

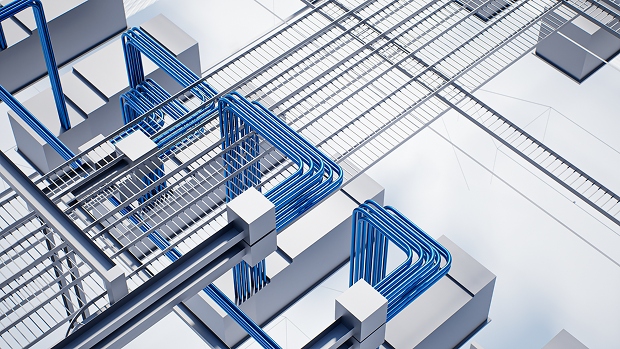

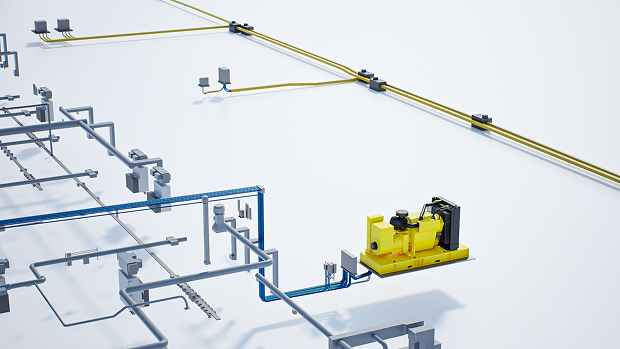

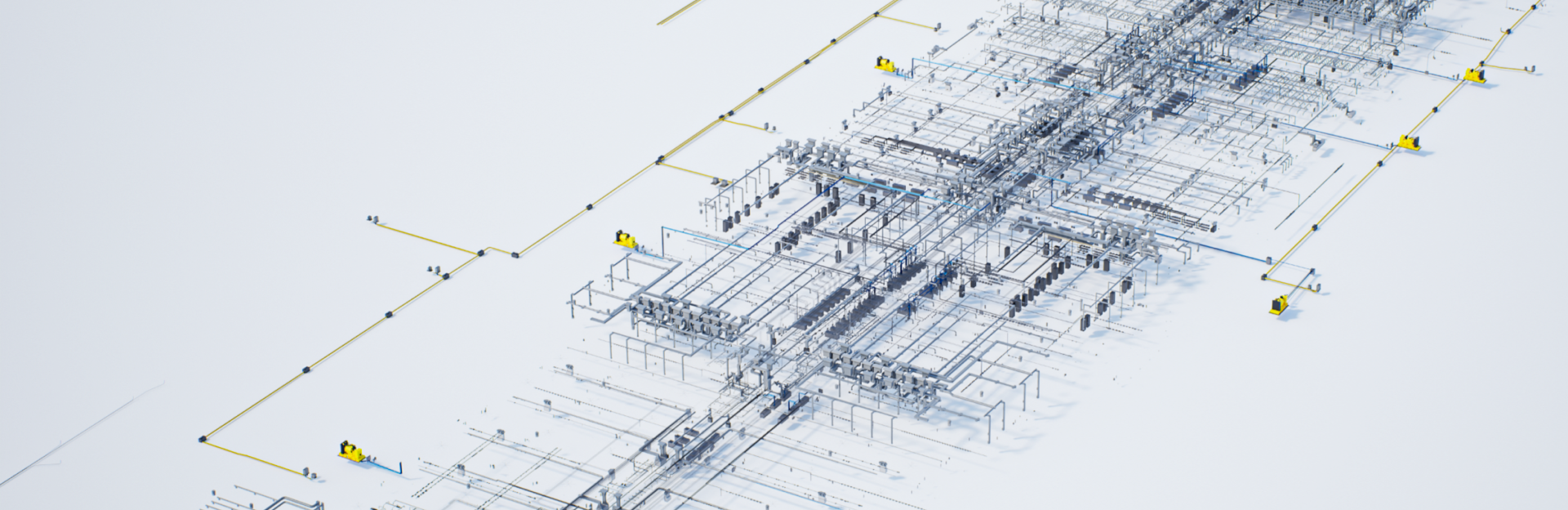

SJS developed a constructible MV duct bank model with precise slopes, straight alignments, and utility clearances. This accuracy enabled pre-planning complex installations, eliminated costly field changes, and optimized manhole placement for proper conduit entry/exit

Process Optimization

Early-stage BIM coordination resolved spatial conflicts before construction, streamlining routing approvals and preventing redesign delays. Integrated trench profiles and elevation data improved excavation planning, material staging, and on-site efficiency.

Clear Alignment

Regular BIM meetings and model-sharing cycles ensured coordination with contractors, civil teams, and utilities. A centralized issue-tracking system kept routing constraints, field updates, and inspection requirements aligned across all stakeholders.

Quality Assurance

Rigorous internal reviews verified constructibility, clearances, and MV standards compliance. Checklists ensured correct slopes, straight runs, and manhole transitions, while QA/QC audits confirmed field readiness and met client expectations.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Impact on the Team

By solving challenges with fiberglass conduits, tight alignment, and utility congestion, we advanced our technical and coordination skills. The project refined constructability reviews, boosted collaboration, and led to new duct bank modeling standards.

Specific Results

We delivered 60,000 ft of MV duct banks with accurate slopes, manhole spacing, and utility clearances. Early conflict resolution minimized redesigns, giving the field team an installation-ready model that streamlined underground construction.

Client Feedback

The client praised the model’s quality and constructibility, noting faster installation and smoother coordination with civil and utility subcontractors. They highlighted the value of early BIM input in preventing costly field adjustments.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037