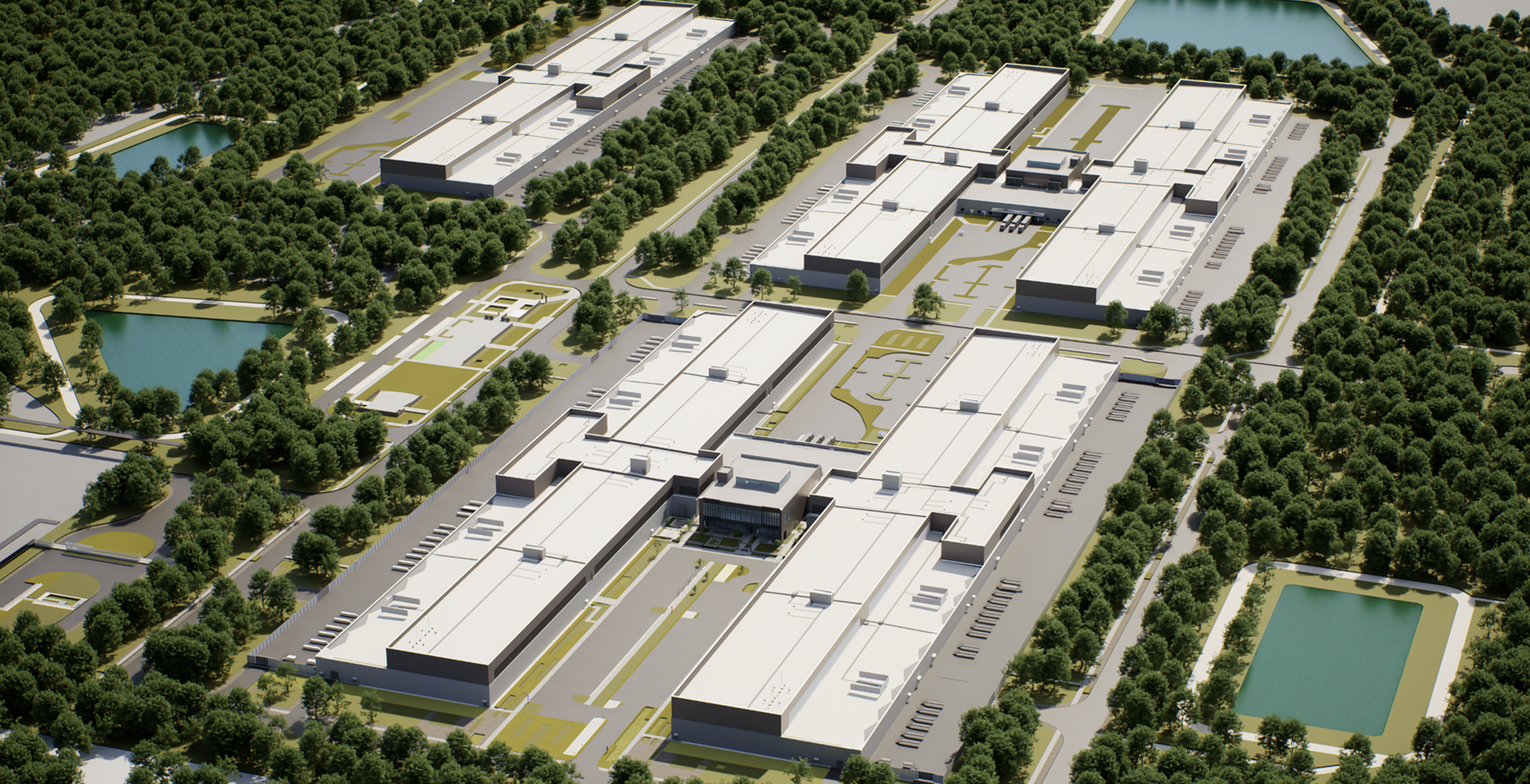

Scope of Work

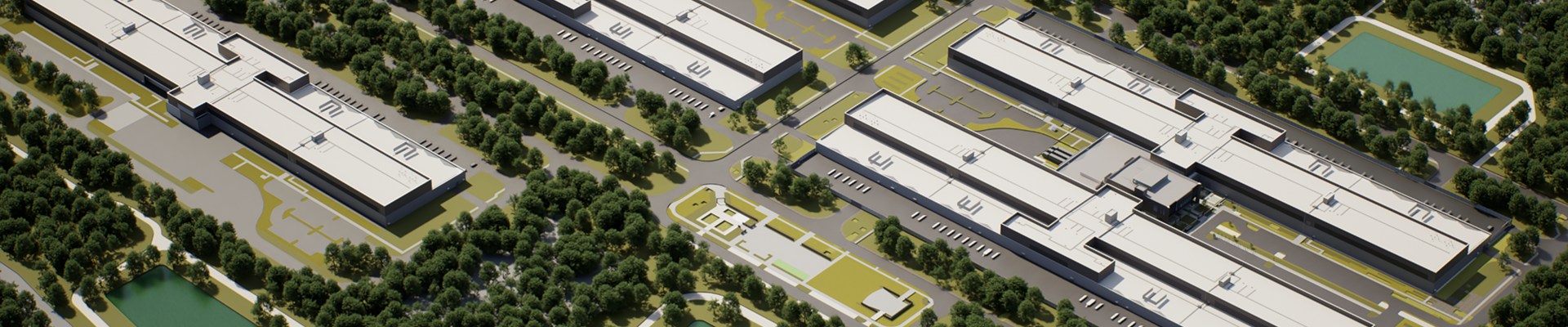

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

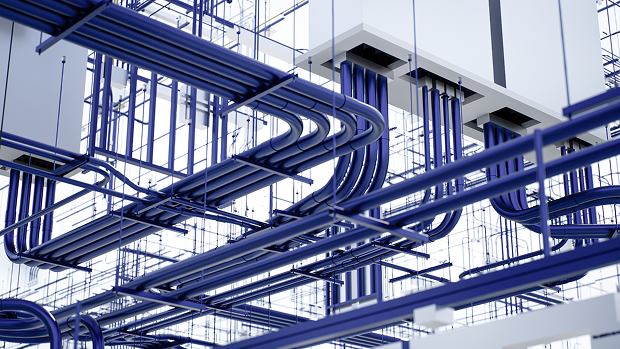

CHALLENGE

Underground conduit routing in a space densely packed with other trades required precise coordination to avoid conflicts, maintain proper spacing, and comply with design and safety standards.

SOLUTIONS WE PROVIDED

- Applied careful planning to optimize conduit routing in a congested environment.

- Ensured precise execution to maintain required spacing and avoid clashes.

- Maintained constant communication with the team to resolve issues promptly.

Project Goals

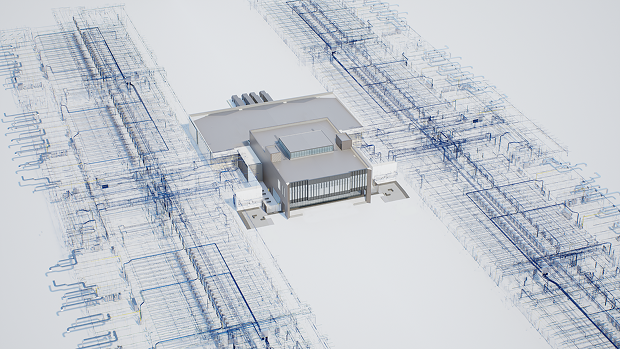

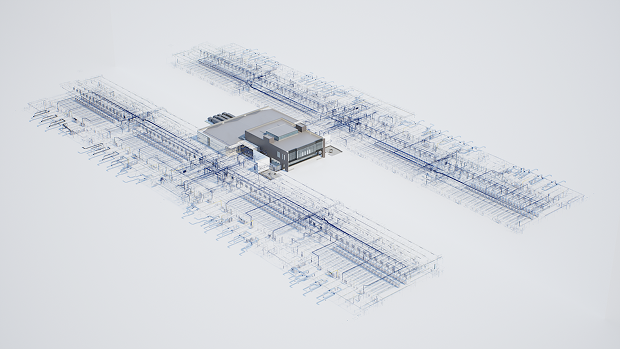

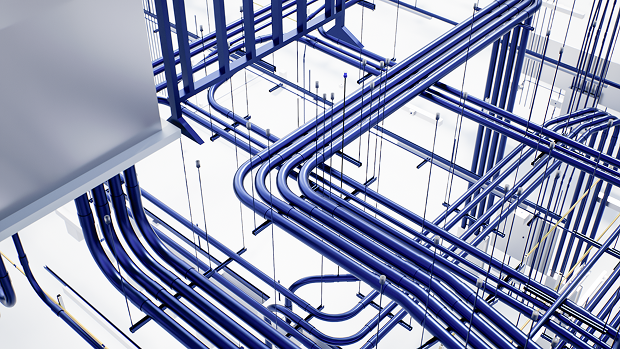

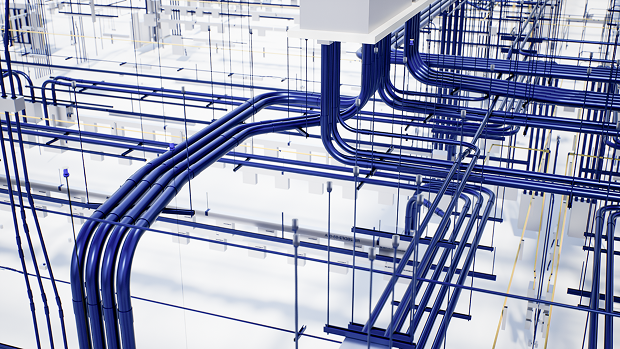

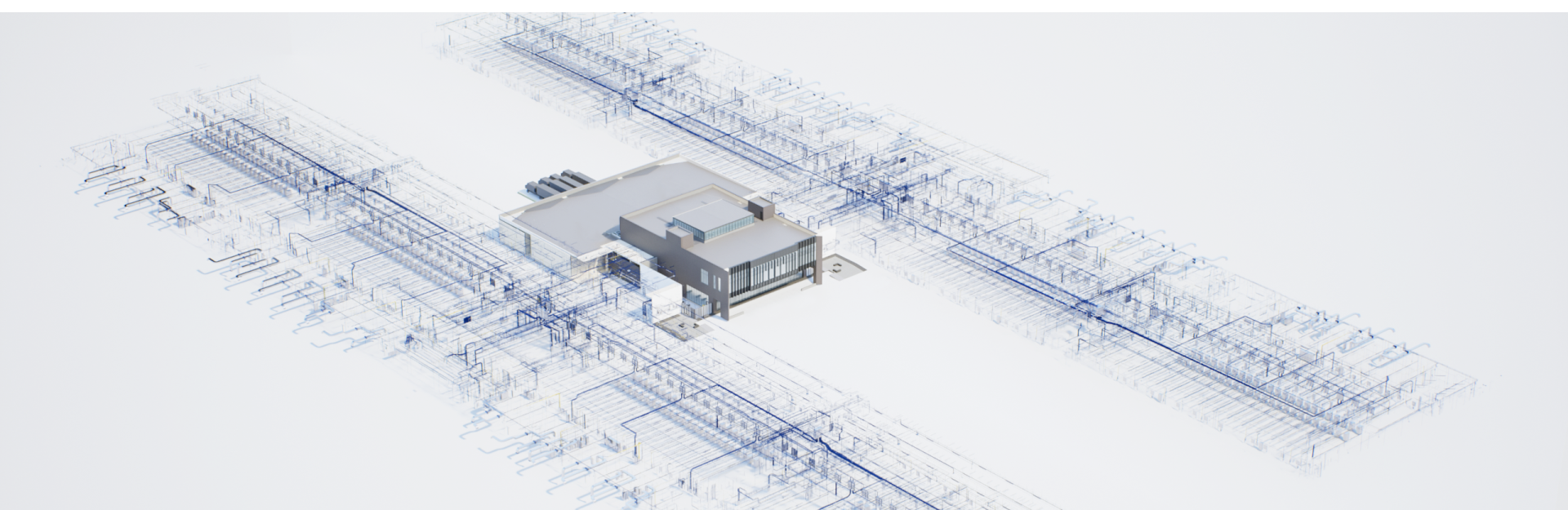

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework. Shop drawings creation and AS-Built model update after installation.

Proven Advantages

Innovative Solutions

A strategic combination of underslab, inslab, and overhead conduit routing was implemented to create an efficient and well-coordinated electrical system, ensuring optimal design in both open spaces and highly congested areas.

Process Optimization

The precise modeling of materials and quantities, along with a high level of detail in the BIM model, enabled the implementation of overhead prefabrication. As a result, off-site manufacturing was facilitated, leading to significant time savings, reduced labor costs, and minimized material waste.

Clear Alignment

Our team ensured efficient communication with the customer through well-prepared weekly meetings. The "Issue Log" tracked pending questions blocking our scope, ensuring nothing was missed and enabling quick customer responses and RFI submissions.

Quality Assurance

Performed internal audits and applied regular corrective and preventive actions to maintain standard compliance. Used checklists to verify accuracy and ensure all outputs met field and client requirements.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Specific Results

Through precise BIM modeling of materials and quantities, we enabled overhead prefabrication, even though it was not planned. This allowed off-site manufacturing, saving significant time, cutting labor costs, and reducing material waste.

Impact on the Team

By managing complex coordination and tight schedules under frequent changes, the team built an efficient process for tracking requirements and modifications. This streamlined method now strengthens workflow efficiency across multiple projects.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037