Scope of Work

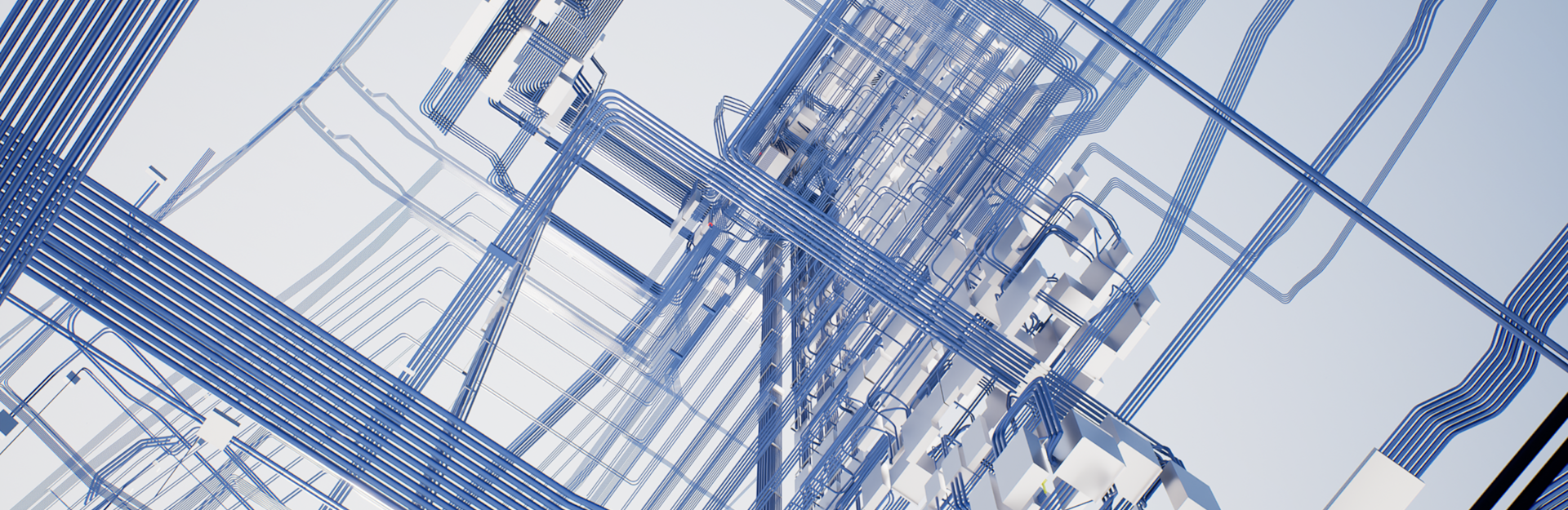

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

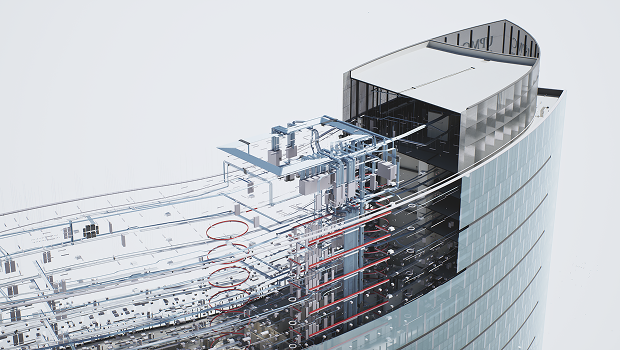

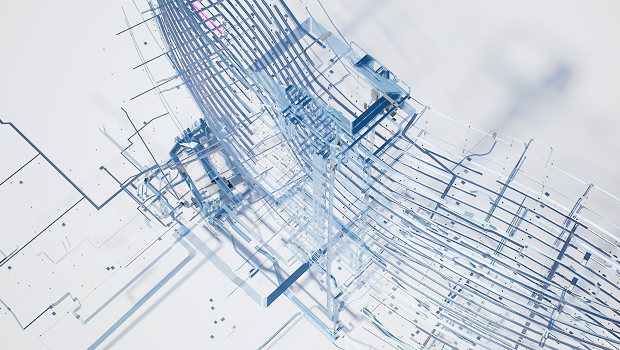

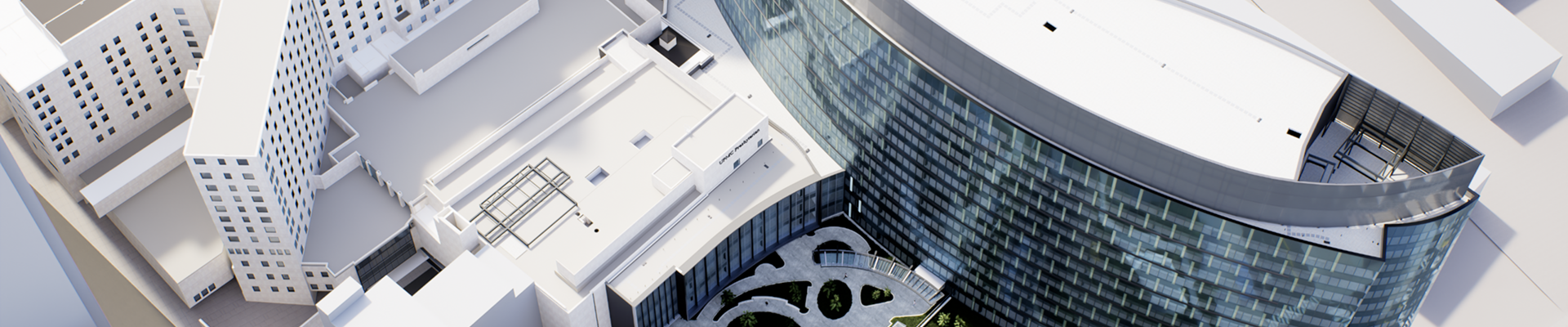

The building’s architectural complexity — with curved walls and no right angles — created significant feeder coordination challenges. Routing was further complicated by a congested main electrical room, where limited space had to be shared with dense equipment and competing MEP systems. As a 17-story hospital, the building had very narrow risers, making vertical conduit placement challenging and requiring creative space management and precise planning.

SOLUTIONS WE PROVIDED

- Developed routing strategies adapted to curved walls and non-standard angles.

- Optimized space usage in the main electrical room to accommodate equipment and MEP systems.

- Planned vertical conduit runs to fit narrow risers through creative space allocation and detailed coordination.

Project Goals

Goal was to complete the full set of modeling and drawings examples in short tems based on the desig, that very massively changed 3 times over the project.

Proven Advantages

Innovative Solutions

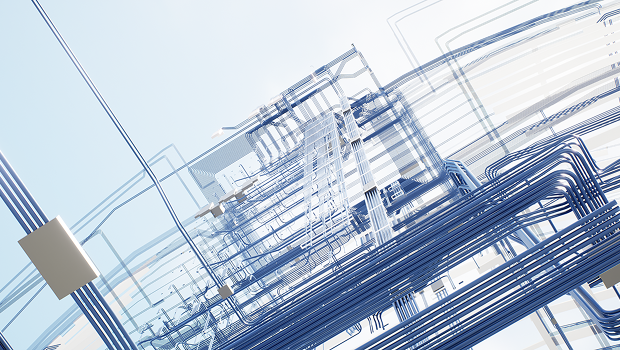

Instead of basket tray modeling was desided to model only the required clearance and leave basket tray location flexible for the field.

Process Optimization

Additional tools for automated Voltage Drop calculations. Revizto implementation with deeper integration of QC and production teams, higher level of synergy btw QC and implementation, issues with open items and disuccions. Binder implementation using ACC.

Clear Alignment

Daily meetings with team and project lead, regular meetings with Client to sync up progress and split workload btw client and SJS production teams.

Quality Assurance

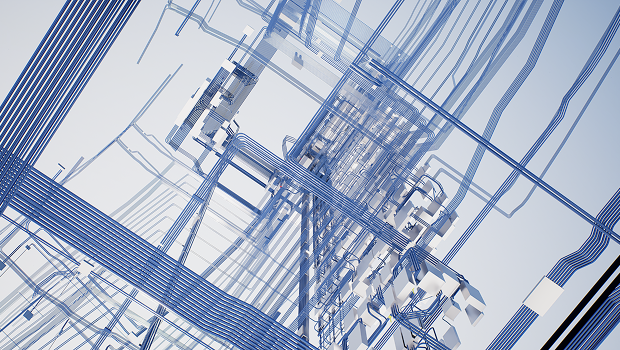

Regular QCs from the construtability review, clash detection, complience with specifications and project/client requirements.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Results

Successfully delivered the full scope on time with a well-coordinated BIM model, ensuring efficiency and constructibility.

Specific Results

On-time delivery with optimized costs and improved pathway routing efficiency, ensuring smoother installation and reduced rework.

Impact on the Team

By overcoming complex architecture, strict healthcare standards, and heavy trade coordination, the team sharpened space management and planning skills, strengthened cross-discipline communication, and improved its ability to adapt under pressure.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037