Scope of Work

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

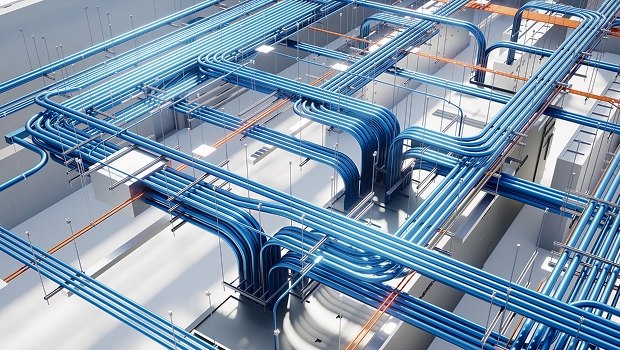

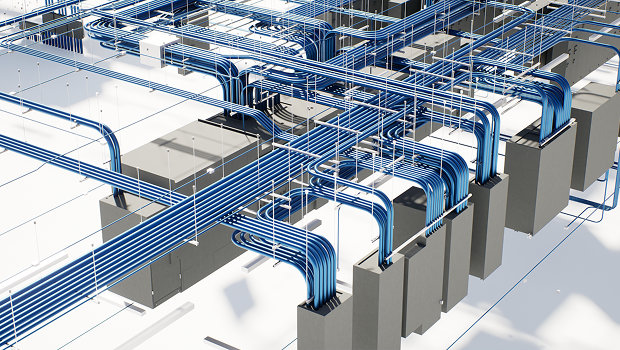

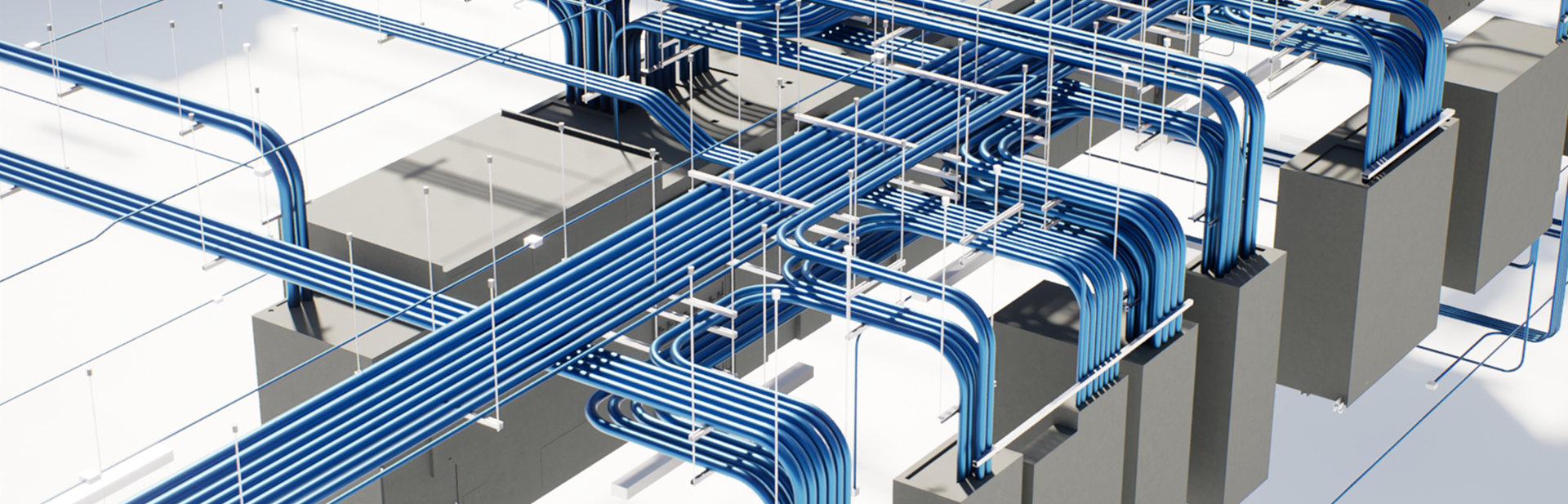

The project’s large scope included ten distinct areas, each functioning almost like a separate project. Some rooms were heavily congested with equipment and trades, requiring systems to be coordinated with only a few inches of clearance between them.

SOLUTIONS WE PROVIDED

- Treated each area as a distinct coordination effort to address its unique requirements

- Applied precise multi-trade coordination to manage congested rooms with minimal clearances

Project Goals

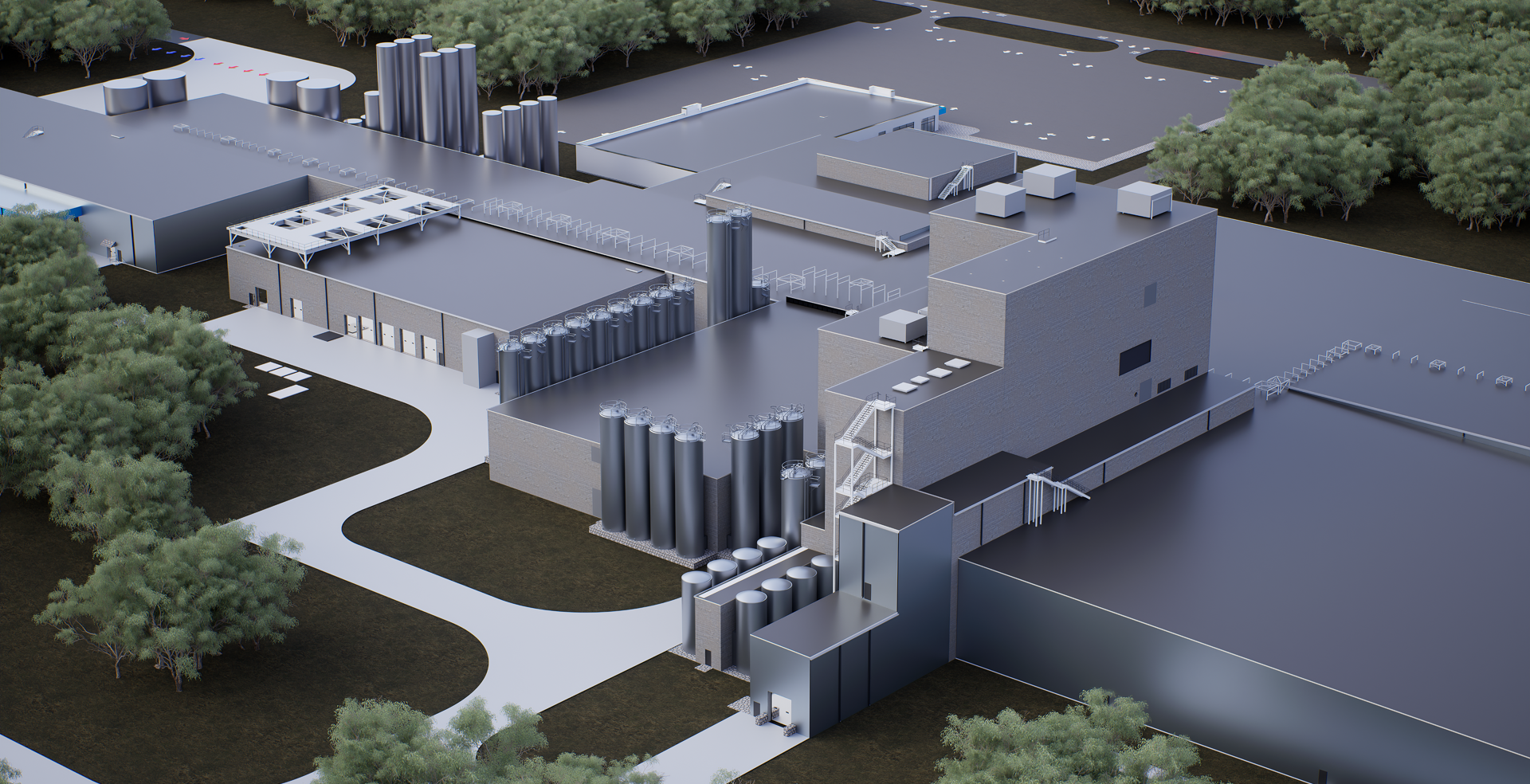

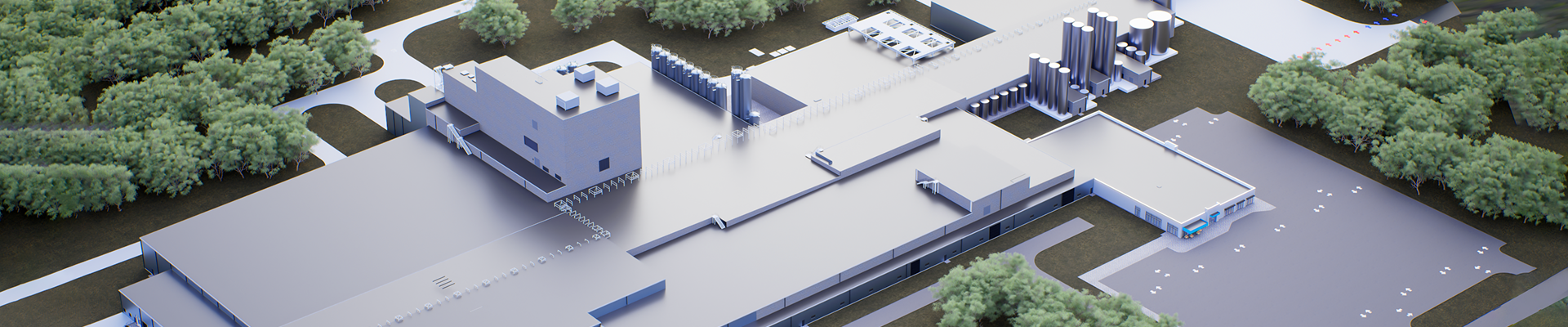

Achieving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework. Making sure field team has what they need and when they need it to go along the construction schedule.

Proven Advantages

Innovative Solutions

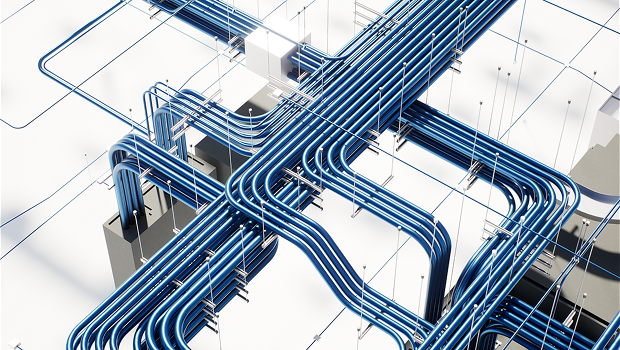

An effective distribution of conduits on racks and careful planning of routings were implemented to create an efficient and well-coordinated electrical system, ensuring optimal design in both open spaces and highly congested areas.

Process Optimization

The production team was divided into separate design groups with their own tasks, specialties, and responsibilities, ensuring high-quality output and streamlining processes and communication. This improved both speed and efficiency, delivering the best possible results.

Clear Alignment

Frequent coordination meeting, one shared live coordination model and communication with client ensured high quality of electrical system on the project

Quality Assurance

Various matrices of requirements, regular corrective and preventative actions for maintaining standard compliance, checklists, client's involvement in model QC.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Specific Results

All areas with special requirements were fully modeled and coordinated in compliance with sanitary codes and standards.

Impact on the Team

Our first experience with a project of this scale led to the development of many new internal and external processes. These improvements continue to support quality assurance and strengthen the reliability of our BIM models today.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037