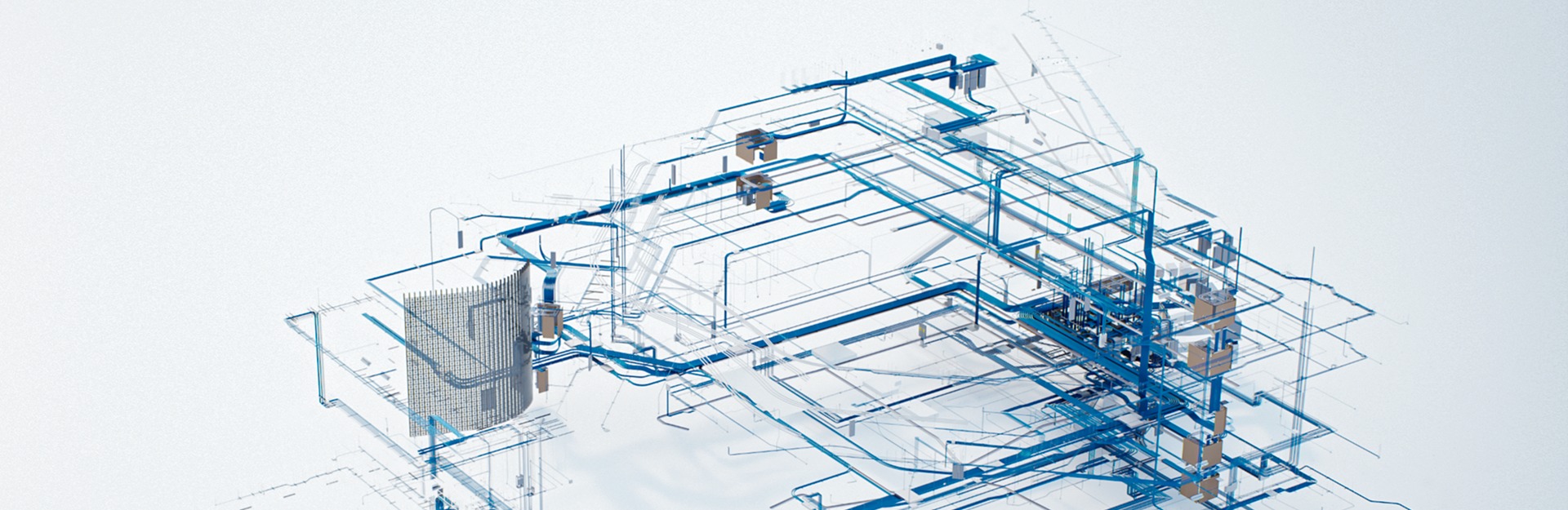

Scope of Work

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

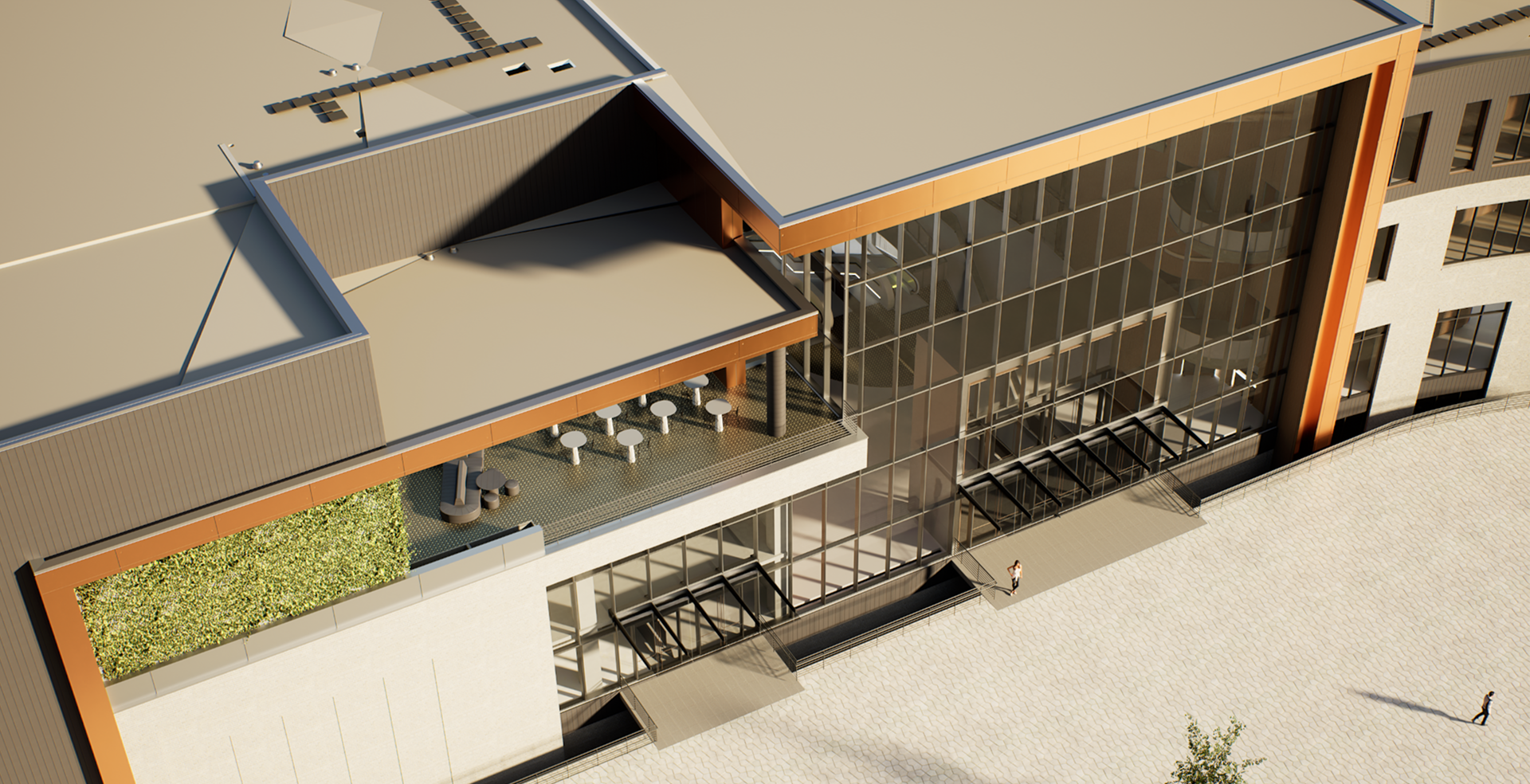

The building’s unique architectural form, expansive open spaces, and integration of multiple systems created a complex environment that demanded innovative coordination strategies.

SOLUTIONS WE PROVIDED

- The team balanced architectural vision with engineering efficiency, integrating MEP systems to preserve aesthetics while ensuring constructability and reliability.

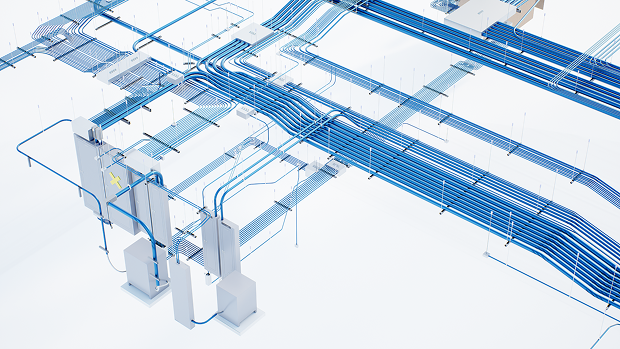

- We created custom routing strategies, using non-standard conduit layouts to keep open spaces while supporting the vision and efficiency.

- We ran detailed load and support calculations for inserts and hangers to ensure stability while maintaining the vision and reliability.

- We applied strict QA/QC checks, ensuring constructability and alignment. As a result, we avoided overruns and kept steady progress

Project Goals

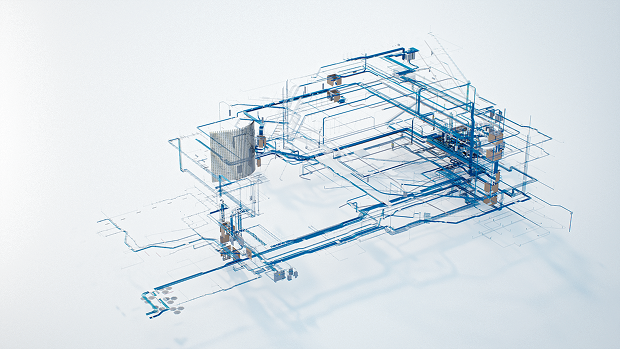

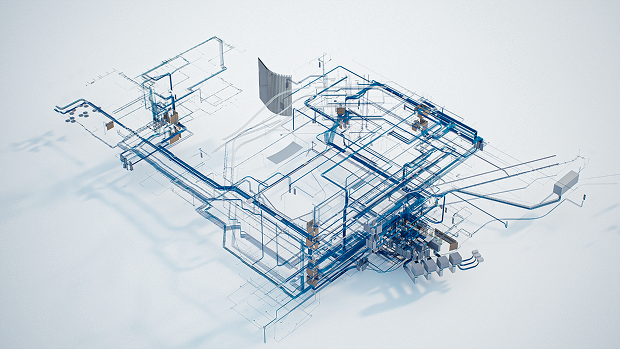

Archiving as detailed BIM model of electrical systems as possible to ensure proper planning and coordination to minimize rework.

Proven Advantages

Innovative Solutions

By leveraging early-stage BIM coordination, SJS was able to identify and resolve spatial conflicts well before construction. This proactive approach streamlined the approval process for routing strategies and eliminated delays associated with field redesigns.

Process Optimization

Detailed BIM modeling of materials and quantities enabled overhead prefabrication, even though it was not initially planned. This approach streamlined off-site manufacturing, saving time, cutting labor costs, and reducing material waste.

Clear Alignment

To improve coordination and workflows, weekly meetings were introduced, enabling faster issue resolution and clarity of responsibilities. This approach improved cross-discipline alignment, reinforced the BIM Execution Plan, and allowed quick adaptation to project changes.

Quality Assurance

SJS conducted strict model reviews with audits and checklists to ensure constructibility. Corrective actions resolved issues early, while QA/QC checks verified runs, slopes, and manhole transitions. All outputs were reviewed for field readiness and client alignment.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Impact on the Team

By overcoming space limits, in-slab conduit demands, and busway integration, we improved cross-discipline collaboration and issue resolution. This coordination standard now drives greater efficiency and proactive problem-solving in future projects.

Specific Results

Through precise BIM modeling of materials and quantities, we achieved overhead prefabrication, even though it was not originally planned. This resulted in off-site manufacturing, delivering time savings, lower labor costs, and reduced material waste.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037