Scope of Work

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

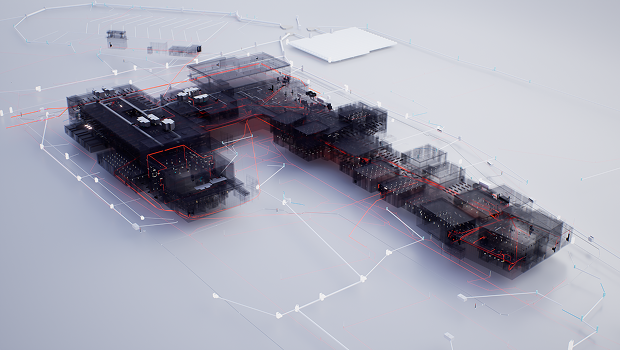

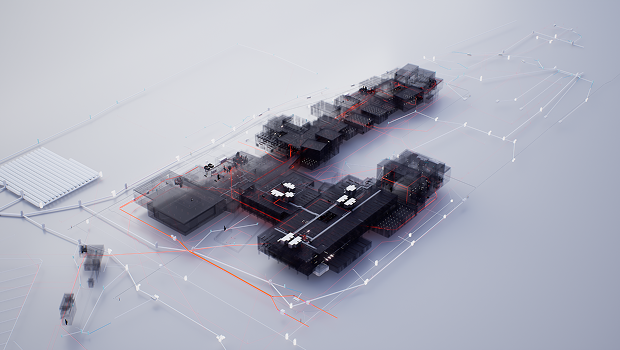

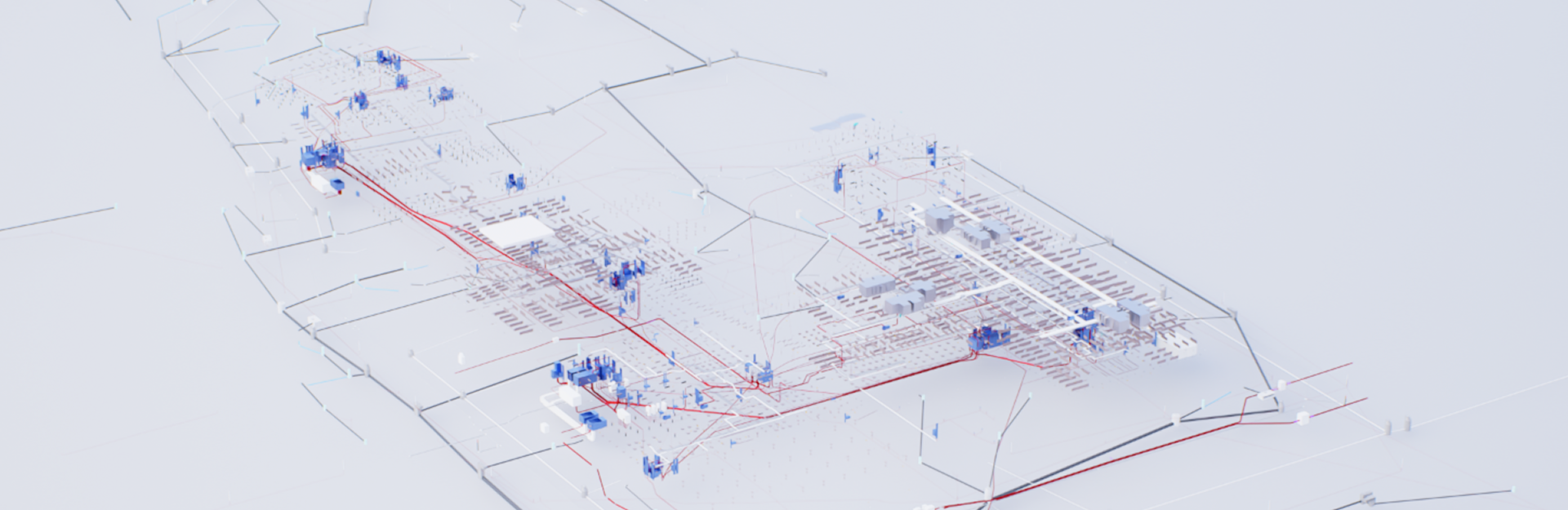

The huge site required a pole-to-load chain connection and complex underground routing due to hard foundation conditions and a large number of underground feeder connections. Part of the building was positioned at a non-typical 6–7° angle, while another section had a unique split-level configuration — four floors instead of three, but with the same overall block height. Additionally, overcrowded corridors were frequently blocked by other trades, requiring an efficient and space-conscious basket tray routing solution.

SOLUTIONS WE PROVIDED

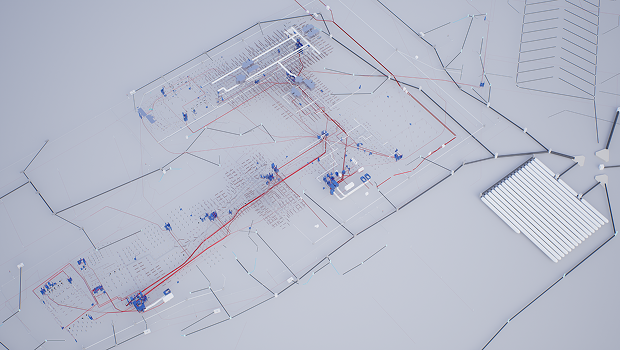

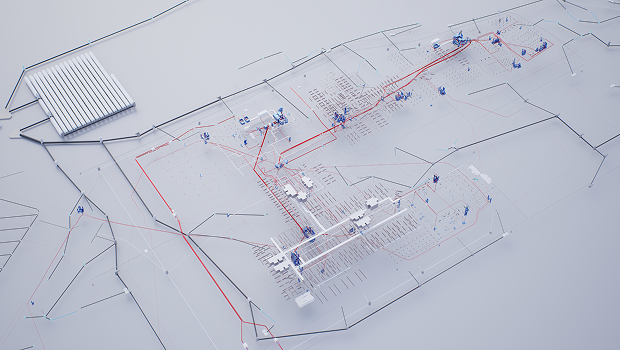

- Designed underground routing plans adapted to the foundation conditions and multiple feeder connections.

- Accounted for non-standard angles and split-level configurations in routing and modeling.

- Developed an efficient basket tray layout to navigate congested corridors without impacting accessibility.

Project Goals

Goal was to complete the full set of modeling and drawings examples in short tems based on the desig, that very massively changed 3 times over the project.

Proven Advantages

Innovative Solutions

Instead of basket tray modeling was desided to model only the required clearance and leave basket tray location flexible for the field.

Process Optimization

Additional tools for automated Voltage Drop calculations. Revizto implementation with deeper integration of QC and production teams, higher level of synergy btw QC and implementation, issues with open items and disuccions. Binder implementation using ACC.

Clear Alignment

Daily meetings with team and project lead, regular meetings with Client to sync up progress and split workload btw client and SJS production teams.

Quality Assurance

Regular QCs from the construtability review, clash detection, complience with specifications and project/client requirements.

Results and Achievements

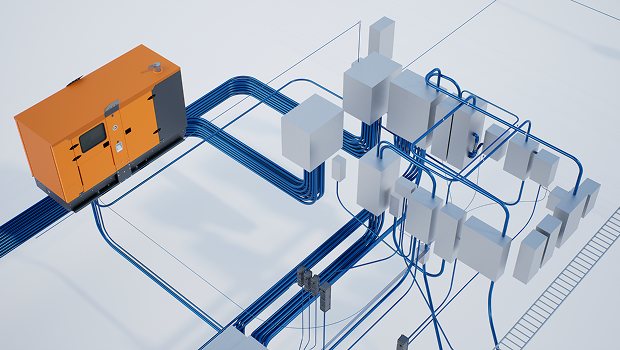

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Results

We delivered 160,000 ft of PVC and EMT conduits ranging from ¾ inch to 4 inches. A total of 12,200 clashes were resolved and 670 sheets were produced, providing the client with accurate documentation and streamlined coordination for installation.

Specific Results

To reduce installation costs, most overhead conduits on Level 1 were relocated under the slab. Nearly all device connections on this level were shifted to the under-slab system, streamlining installation and improving overall efficiency.

Impact on the Team

The team gained experience in under-slab and underground modeling, plus exposure to theater systems. We introduced new drawing tracking methods and built in-house tools that boosted modeling speed, QC, and constructability review.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037