Scope of Work

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

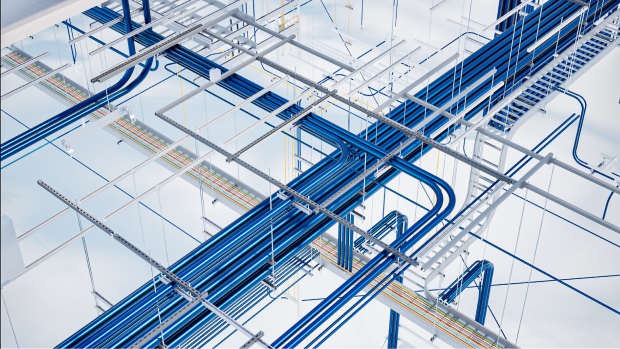

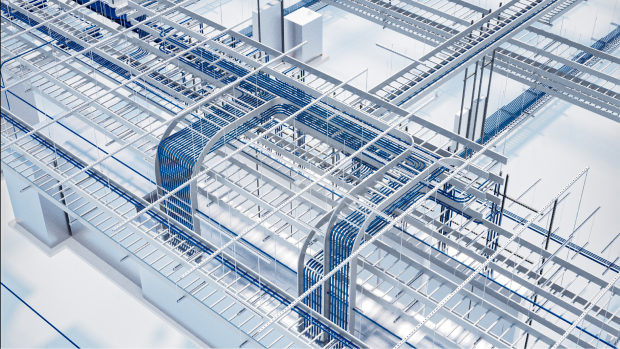

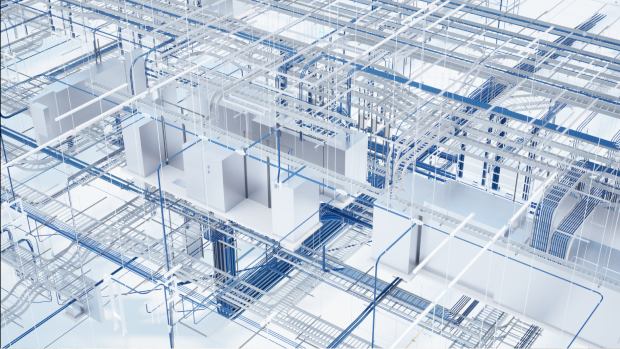

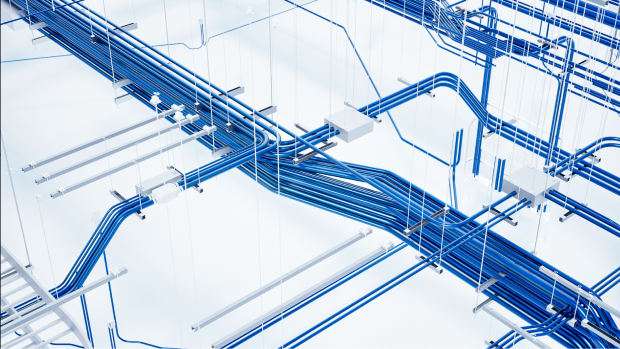

The project required a large number of control devices, grouped by panels and varying by type, with some needing low-voltage cable routing and others piping connections. The key challenge was accurately interpreting PID diagrams and network schematics within the BIM environment, while also managing non-standard routing conditions that increased coordination complexity.

SOLUTIONS WE PROVIDED

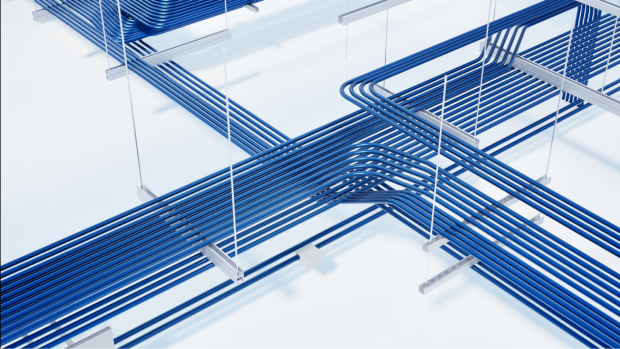

- Interpreted PID diagrams and network schematics directly in BIM to ensure accurate system representation

- Coordinated non-standard routing conditions to maintain constructability and system integrity

Project Goals

Archiving as detailed BIM model of electrical systems as possible to ensure proper planning and coordination to minimize rework

Proven Advantages

Innovative Solutions

Established a coordination platform in Revizto and introduced a streamlined approach for populating model metadata. This improved information consistency, enhanced searchability, and supported faster design decision-making.

Process Optimization

Applied modular solutions, pre-modeling strategies, and detailed layout drawings to optimize routing. This improved metadata accuracy, reduced design revisions, and supported efficient field execution.

Clear Alignment

Followed the BIM Execution Plan and held regular coordination meetings, ensuring clear task ownership, faster issue resolution, and consistent project alignment across all teams

Quality Assurance

Conducted clash detection and enforced compliance with project standards. Delivered a clash-free model and installation-ready shop drawings to ensure constructibility and smooth field implementation.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Results

The client received a well-coordinated BIM model, a precise BOM, and installation-ready shop drawings. Delivered on time with optimized costs, these outputs enhanced constructibility, streamlined installation, and reduced overall project risks.

Impact on the Team

The team strengthened its expertise in control systems, a rare and complex scope within SJS projects. This experience enhanced technical proficiency and coordination skills, adding lasting value for future projects requiring advanced control solutions.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037