Scope of Work

While working on this project, we carried out a significant scope of work that included:

Challenges and Solutions

CHALLENGE

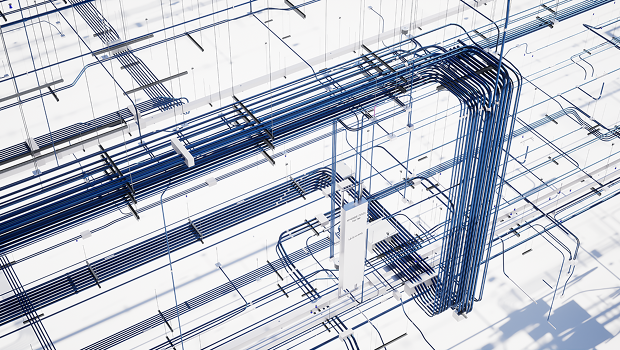

The multipurpose building included diverse areas with different requirements — from large public spaces featuring non-typical curved lighting fixtures to highly constrained technical areas. This combination made coordination particularly challenging.

SOLUTIONS WE PROVIDED

- Coordinated installation of curved lighting fixtures in public spaces

- Applied detailed planning to resolve tight-space constraints in technical areas

Project Goals

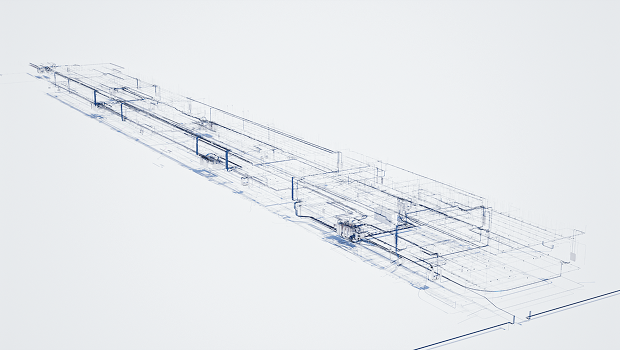

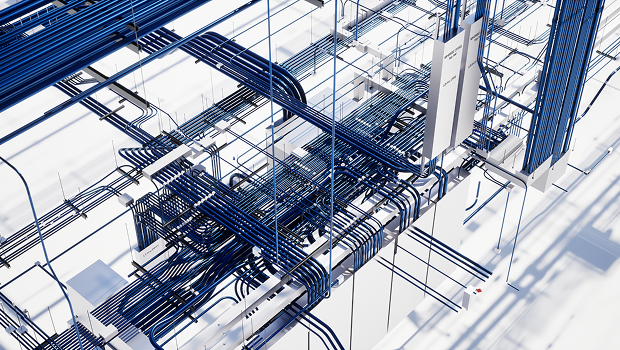

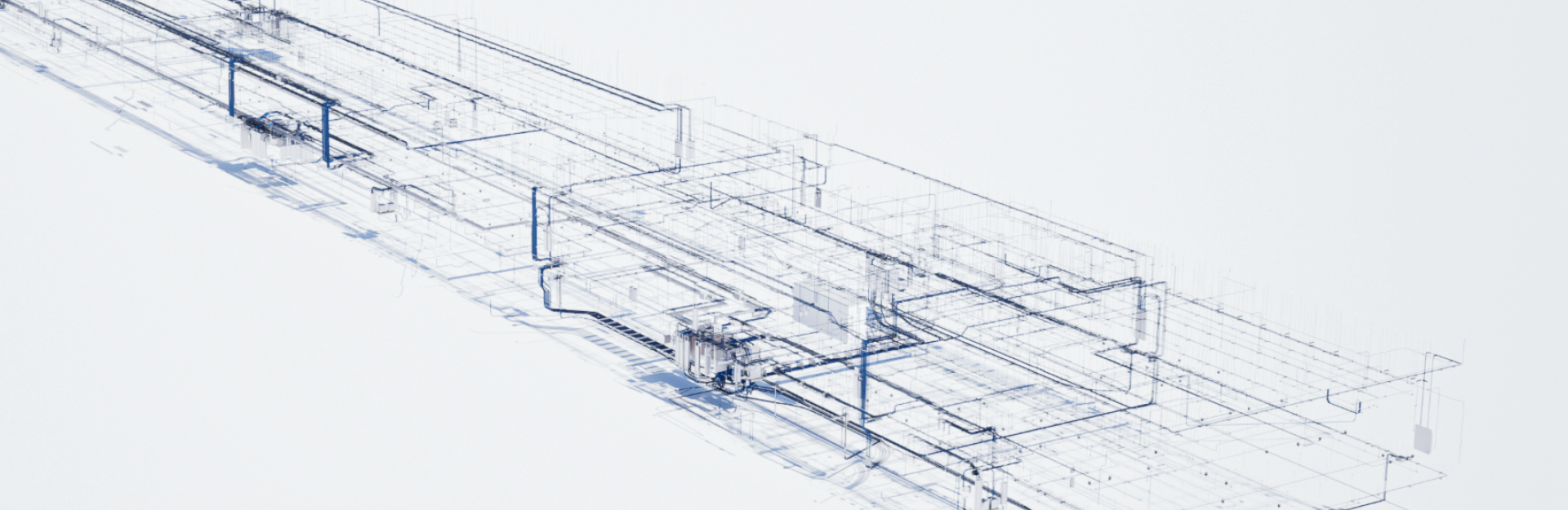

Achieving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework. Making sure field team has what they need and when they need it to go along the construction schedule.

Proven Advantages

Innovative Solutions

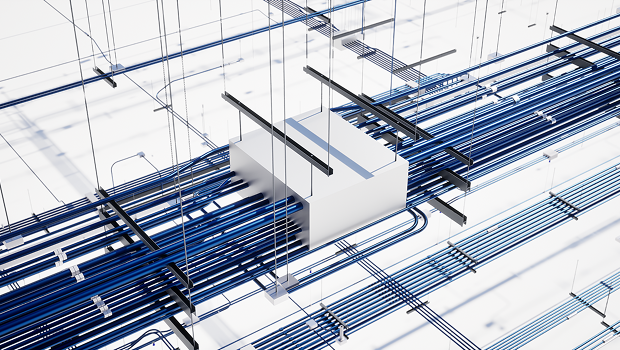

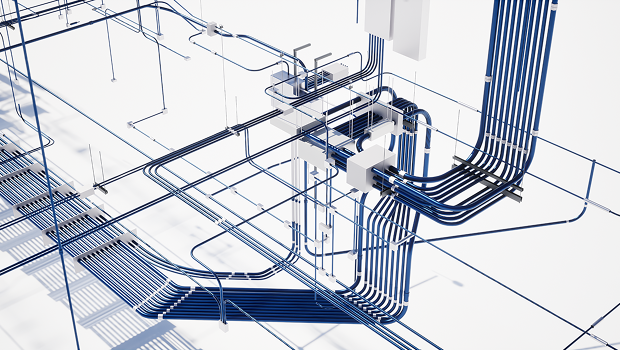

To overcome spatial constraints and clashes in this project our team applied innovative routing with early multi-trade coordination zones. Using BIM, we simulated alternate configurations in real time, reducing revisions and speeding up approvals.

Process Optimization

To address the high volume of RFIs and design bulletins, we restructured our workflow with staged updates and a change-tracking matrix. This reduced rework, improved version control, and enabled quicker adaptation to design changes while sustaining team productivity.

Clear Alignment

Given the project’s fast pace, alignment between the customer and our modeling team was critical. Daily coordination and centralized issue tracking kept stakeholders informed, ensuring prompt responses and reducing delays from miscommunication.

Quality Assurance

We ensured modeling accuracy and compliance on this project through a layered quality assurance approach, including clash detection audits, checklist reviews, and peer verification loops to catch inconsistencies early and uphold standards amid design changes.

Results and Achievements

Archiving as detailed BIM model of electrical systems as posible to ensure proper planning and coordination to minimize rework

Specific Results

We delivered 840 sheets with precise layout points and coordinated drawings, accelerating installation and reducing uncertainties. At close, a full As-Built model with updated drawings ensured accurate documentation for future operations.

Client Feedback

The client praised our performance, noting the quality of coordination, responsiveness to design changes, and accuracy of deliverables. They valued our proactive approach and commitment, which reinforced trust and strengthened collaboration.

Impact on the Team

By managing multi-phase installations, clashes, and constant updates, the team gained hands-on problem-solving experience. The project strengthened technical skills, improved agility under pressure, and deepened knowledge of complex BIM coordination.

Get a Quote

Address:

4549 W Dickman Rd, Springfield, MI 49037